QForm UK

Support and sales of FEM software for metal forming processes

Support and sales of FEM software for metal forming processes

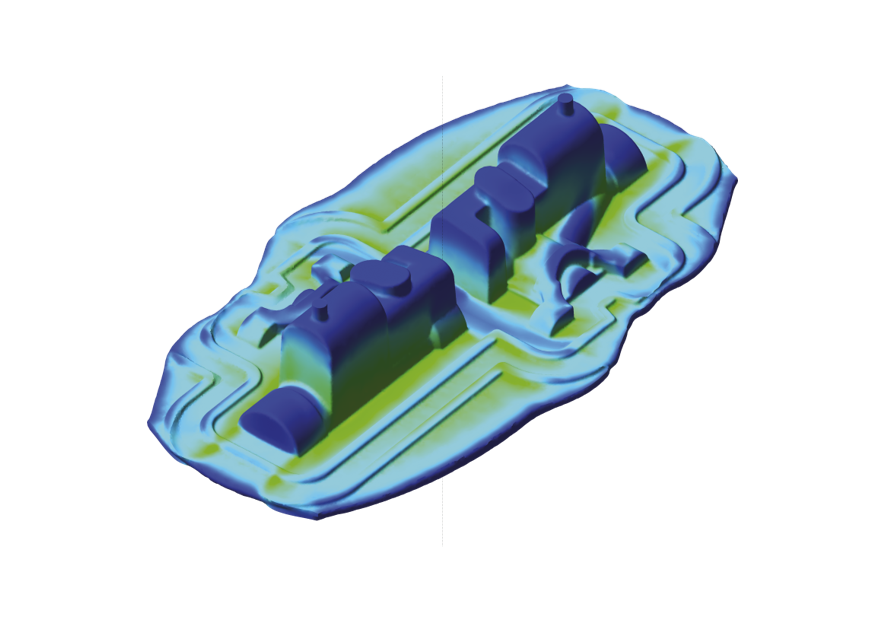

FEM simulation

Metal forming simulation by FEM experts

Metal forming simulation by FEM experts

MatILDa®

The material database with flow curves, CCT database and more

The material database with flow curves, CCT database and more

Materials Consulting

Utilizing material data and models for industry-specific applications

Utilizing material data and models for industry-specific applications

HDQT® Plant

Forming technology for novel property categories: steels, titanium, nickel-based alloys and more

Forming technology for novel property categories: steels, titanium, nickel-based alloys and more

Plant Development

Customized solutions through extensive industry expertise

Customized solutions through extensive industry expertise

Technology Consulting

Industry-specific expertise in metal forming processes and heat treatments

Industry-specific expertise in metal forming processes and heat treatments

R&D Activities

Research & Development about metallic materials as a dedicated SME partner

Research & Development about metallic materials as a dedicated SME partner

News

GMT head office Berlin

Heinersdorfer Str. 12, 13086 Berlin

Gesellschaft für metallurgische Technologie- und Softwareentwicklung mbH

GMT office in Brandenburg

Breitscheidstraße 62, 16321 Bernau

t. +49 3338 334218-10

t. +49 3338 334218-10

Gesellschaft für metallurgische Technologie- und Softwareentwicklung mbH