The flow curves database compiled by experimental investigation

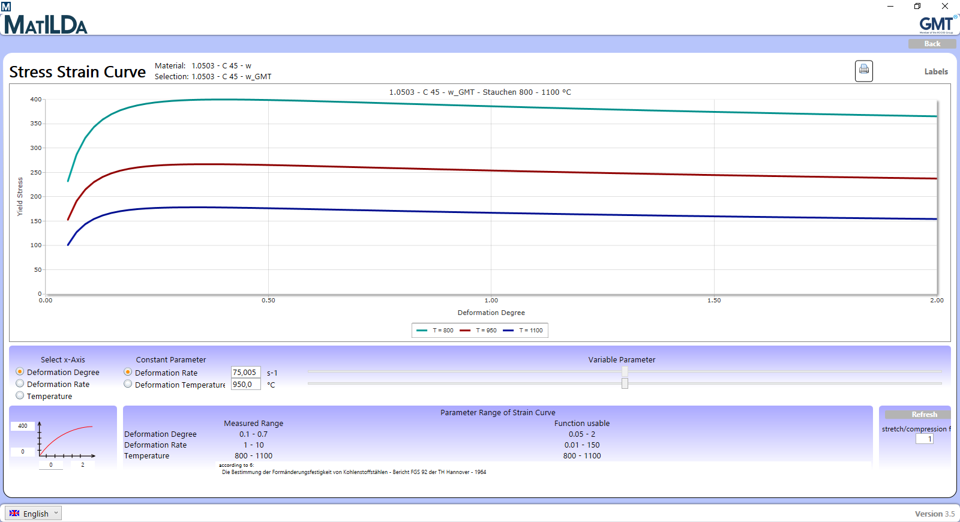

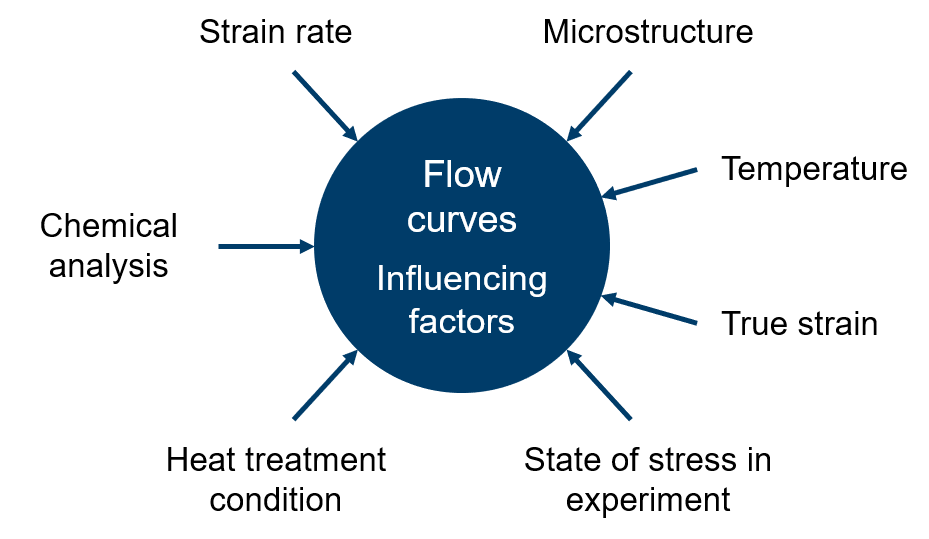

Validated material data sets are necessary to reliably simulate results in forming technology. This also applies to flow curves. The MatILDa® flow curves database contains numerous flow curve data sets based on experimental investigations. Hot flow curves and cold flow curves provide a qualified basis for material calculations as a function of forming temperature, true strain and strain rate in analytical (approximated) or tabular form.

Other important parameters influencing the flow stress, such as the microstructure and the heat treatment condition of the material (e.g. mill-hard, normalized or soft-annealed) as well as the stress condition in the selected forming process (tension, compression or torsion) can be taken from the respective flow curve model and selected according to the conditions in the real forming process.

Validity ranges of flow stress models

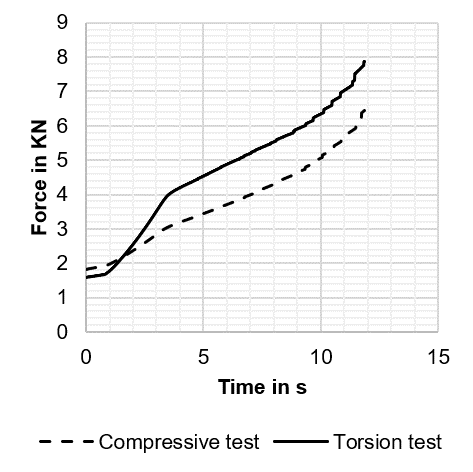

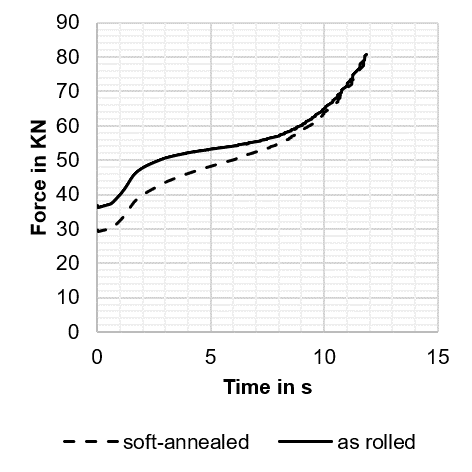

It is also crucial that corresponding validity ranges for flow stress models are specified, which best fit the real process windows. This significant influence can be displayed by simulation results: within the FEM simulation of a common upsetting test, flow curves with different validity ranges from the MatILDa® flow curves database were used. This illustrates that there is a significant difference regarding the resulting force in the FEM results depending on whether a flow curve from an upsetting or a torsion test was used. Likewise, the parameters differ considerably when different heat treatment conditions are applied. The conclusion is that it is very important to select the flow curve data according to the conditions in the process – and not to use flow curves with undefined ranges of validity.

FEM results for an upsetting test using flow curves from the MatILDa® flow curves database with different validity ranges

Type of experimental setting

(100Cr6 / 1.3505, T = 1000 °C)

(100Cr6 / 1.3505, T = 1000 °C)

Heat treatment condition

(41Cr4 / 1.7035, T = 500 °C)

(41Cr4 / 1.7035, T = 500 °C)

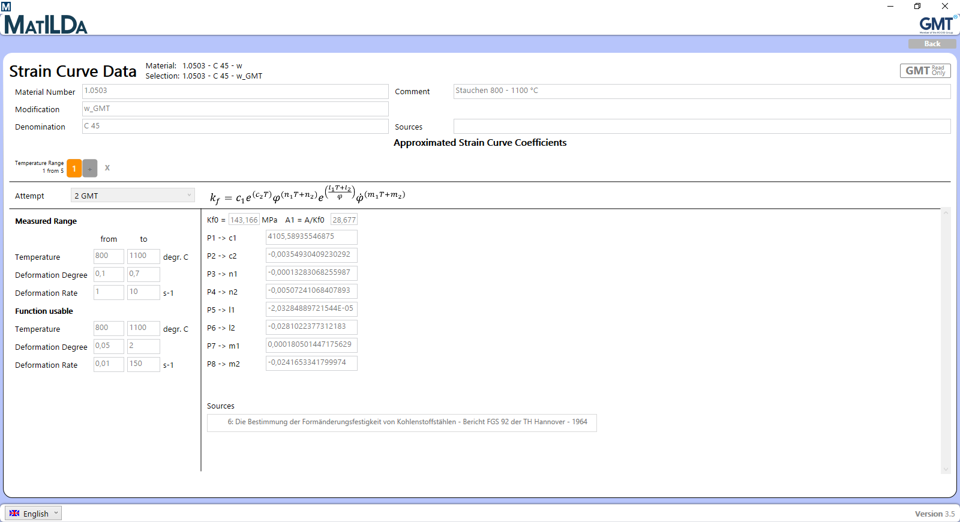

In the MatILDa® flow curve database, ® the validity range of the flow curves can precisely be defined in the parameters Measured range and Function usable. The comment list notes on the experimental settings.

Functionalities of the flow curves database

The flow curve database of MatILDa® includes warm flow curves and cold flow curves of various approaches following Hensel/Spittel and GMT (inclusion of the warm yield point can be achieved by adding an additional term) for metallic materials. The user has the option to either utilize the existing flow curves for a material or integrate their own data in tabular form. The parameterized description of the flow curves can be done using various approaches. Currently, in MatIlDa®, three different multiplicative approaches are considered:

• Hensel/Spittel 1

• Hensel/Spittel 10

• GMT approach

The flow curve database is available for various alloys of steel, non-ferrous metals (e.g. aluminum, copper, zinc) as well as special materials (e.g. titanium, nickel, cobalt).

• Hensel/Spittel 1

• Hensel/Spittel 10

• GMT approach

The flow curve database is available for various alloys of steel, non-ferrous metals (e.g. aluminum, copper, zinc) as well as special materials (e.g. titanium, nickel, cobalt).

Please also read our publications about flow curves:

Ask for more details about our flow curves database!

✔ We have 20+ years of expertise

✔ We successfully advise and support customers from a wide range of industries

✔ Save time & costs through reliable flow curves

✔ Your inquiry is free-of-charge & non-binding

✔ We successfully advise and support customers from a wide range of industries

✔ Save time & costs through reliable flow curves

✔ Your inquiry is free-of-charge & non-binding

Recrystallization model

Enhancing material optimization through microstructure simulation: calculate grain sizes, grain growth and recrystallization processes

MatILDa® materials database

Whether exploring forming technology, heat treatment or other industrial processes, this materials database provides the necessary knowledge!