Optimizing your forming processes with the leading QForm simulation software, our expert team and reliable support

Since 2011, we've been offering a unique package for simulation software QForm: expert advice, professional handling of QForm license sales and reliable support for QForm software products from a single source.

About QForm UK

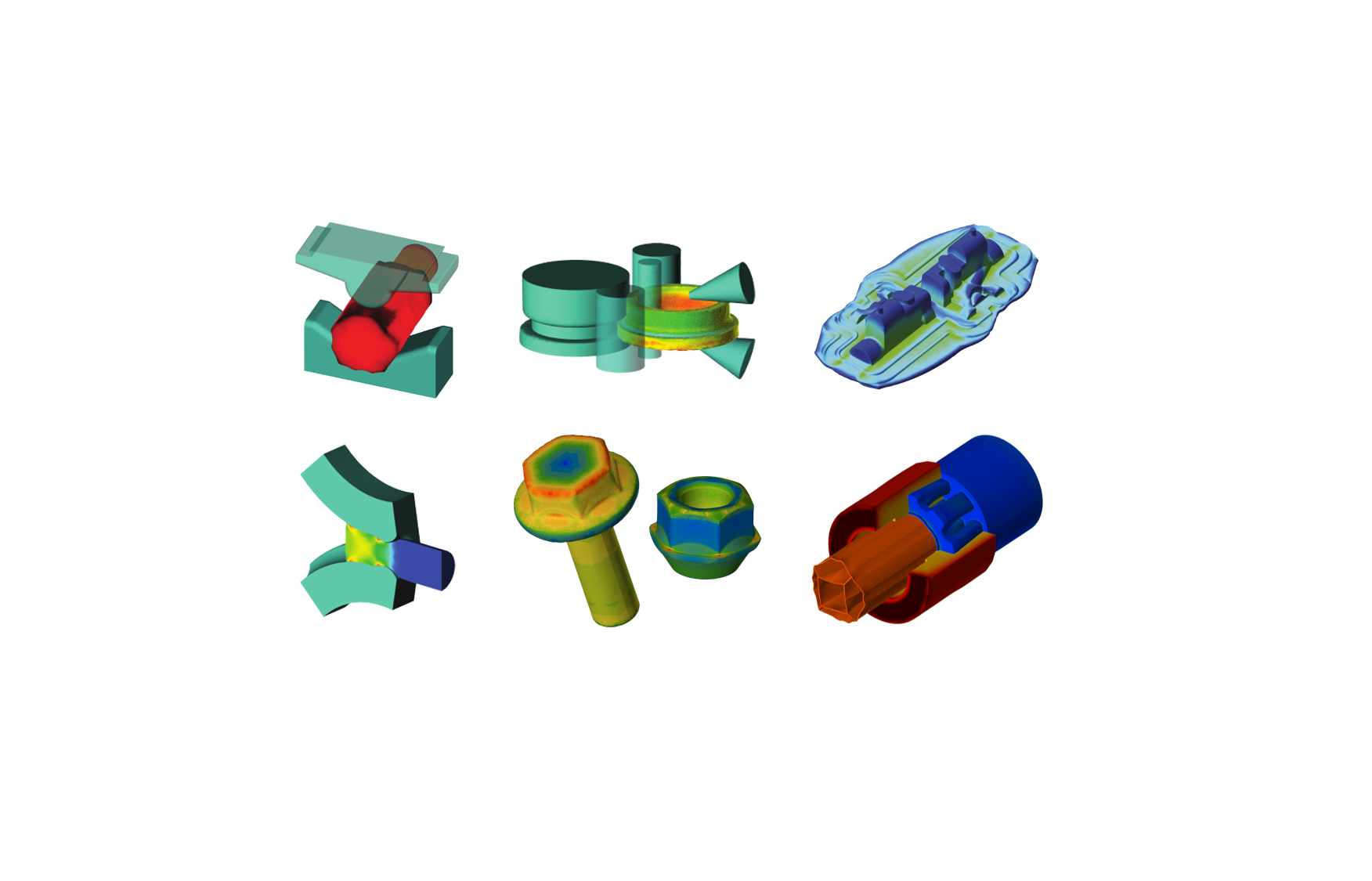

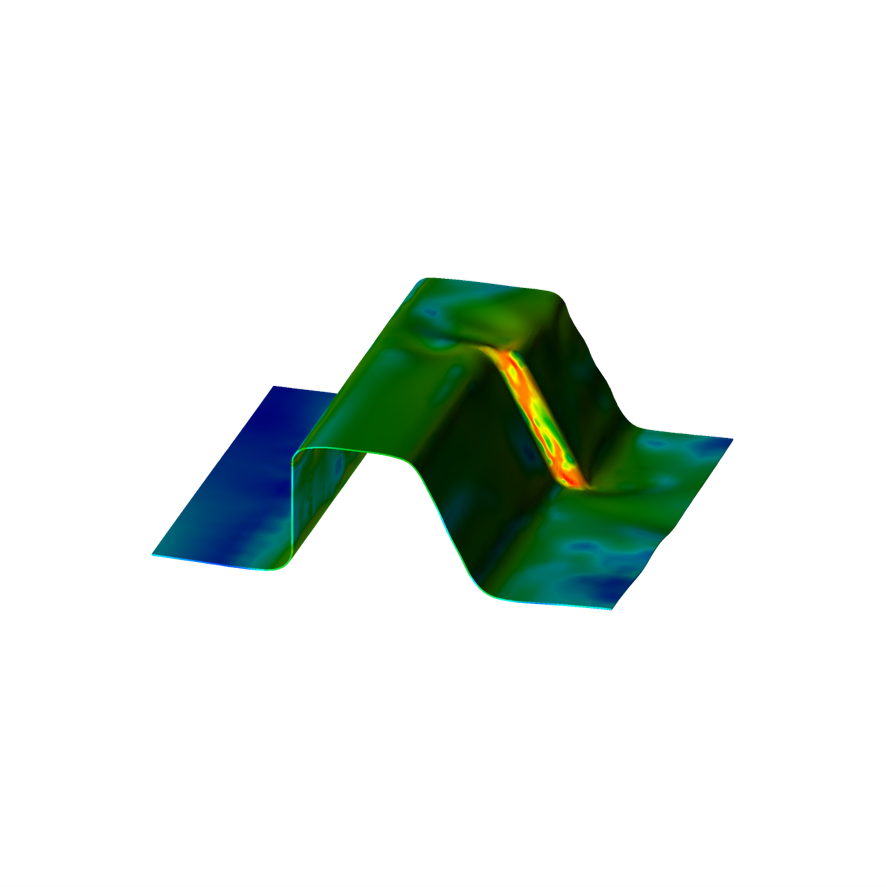

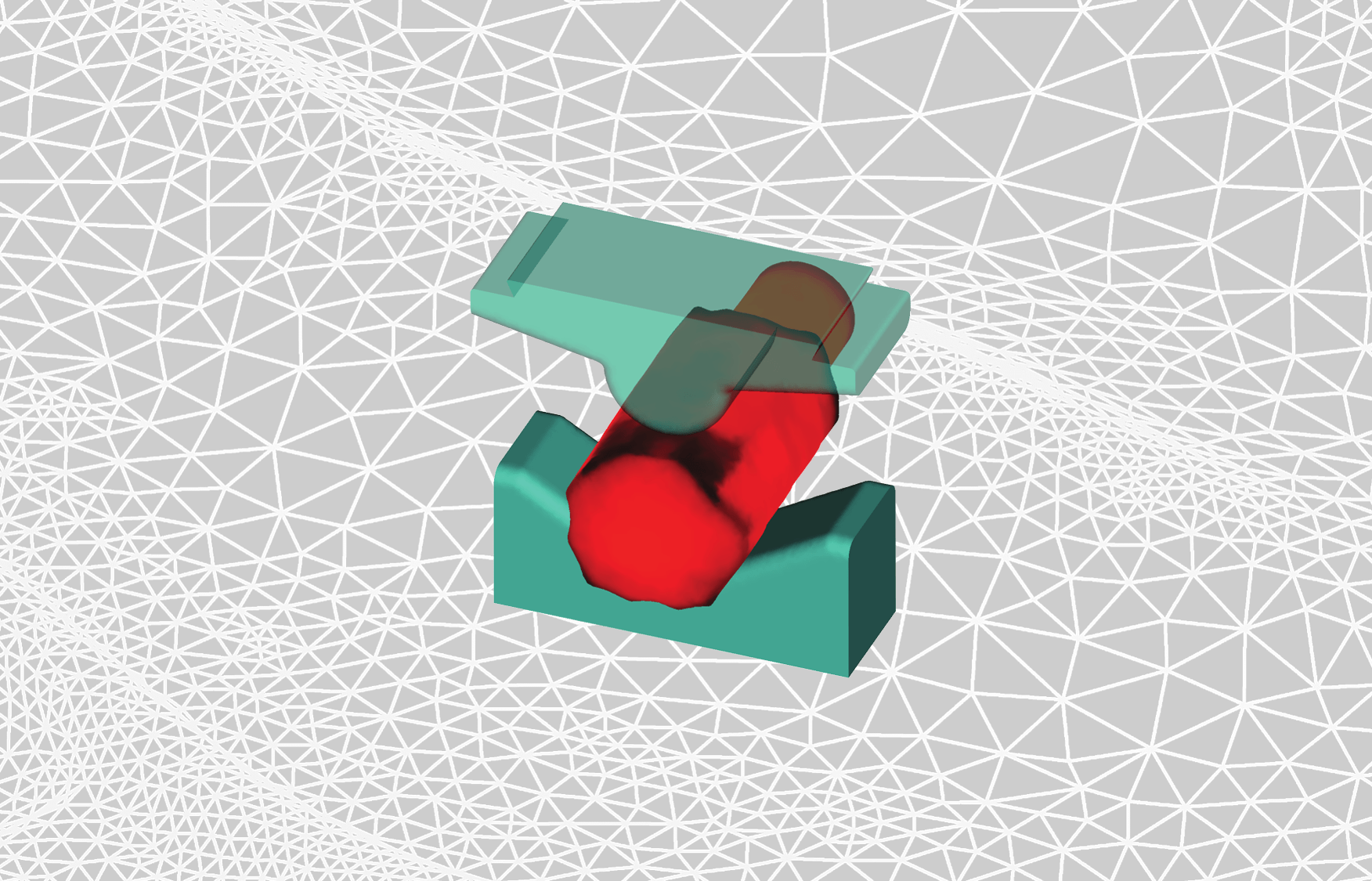

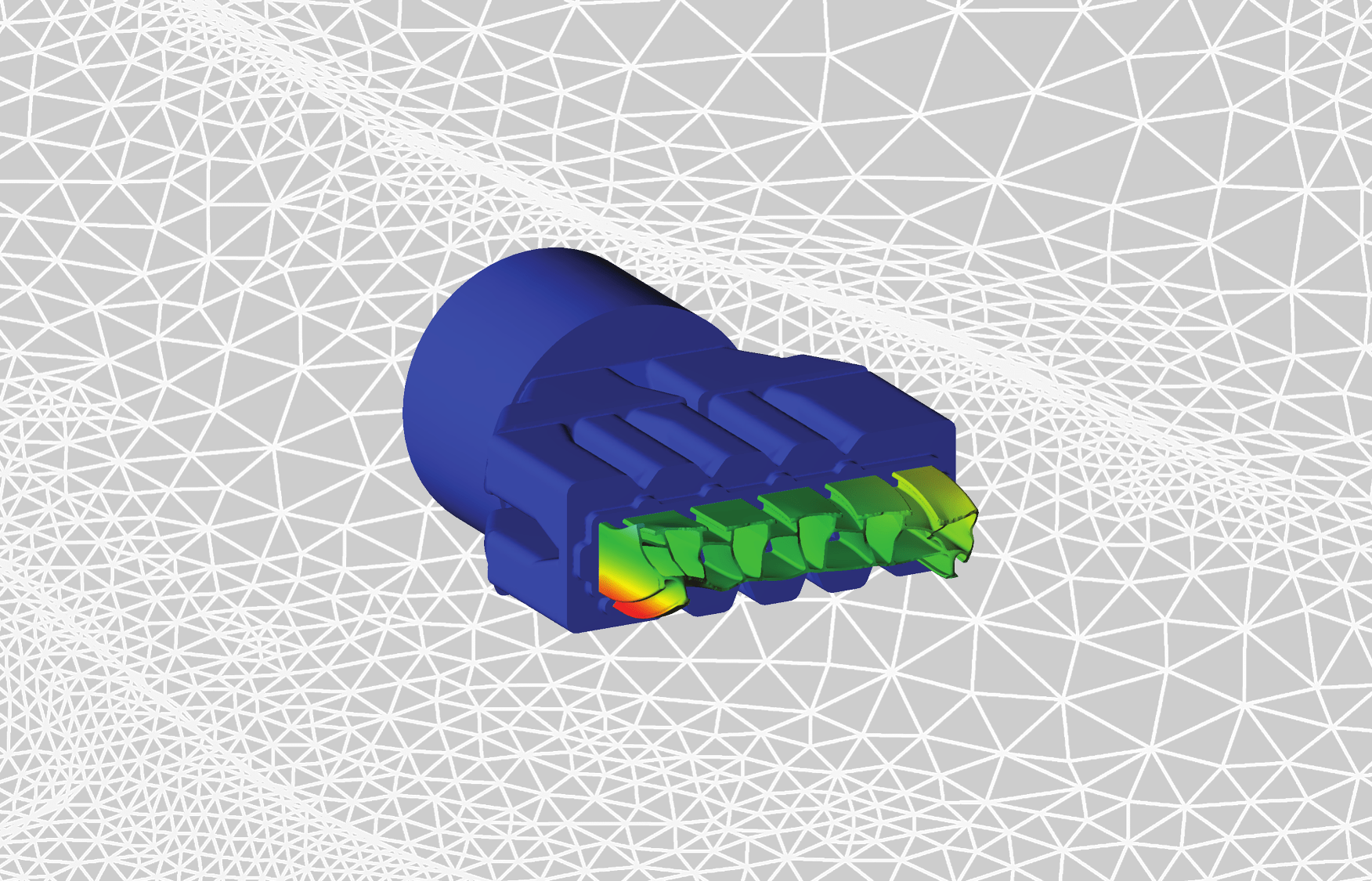

QForm UK is state-of-the-art software designed for simulating nearly all hot and cold forming processes, particularly in the field of bulk forming. Our software includes specific modules for longitudinal rolling, cross-rolling, die forging, open-die forging, ring rolling, extrusion and electric upsetting. QForm allows for fast and reliable simulation of entire technological chains, offering diverse tools for process analysis, calculation of resulting microstructure and phase transformation. It's used in the steel industry, aerospace, automotive, energy sector and many other industries for developing and optimizing forming processes as well as forming tools.

Distribution & Consultation for QForm UK

Since 2011, we've been trusted partners for the distribution and consultation related to QForm UK: a unique period of experience from which you can benefit, too. Our deep insight into the QForm UK products allows us to be actively involved in optimizing the FEM software: If any inconsistencies occur in a simulation, they can be reported directly to the developers and appropriate adjustments can be made, saving you time and resources.

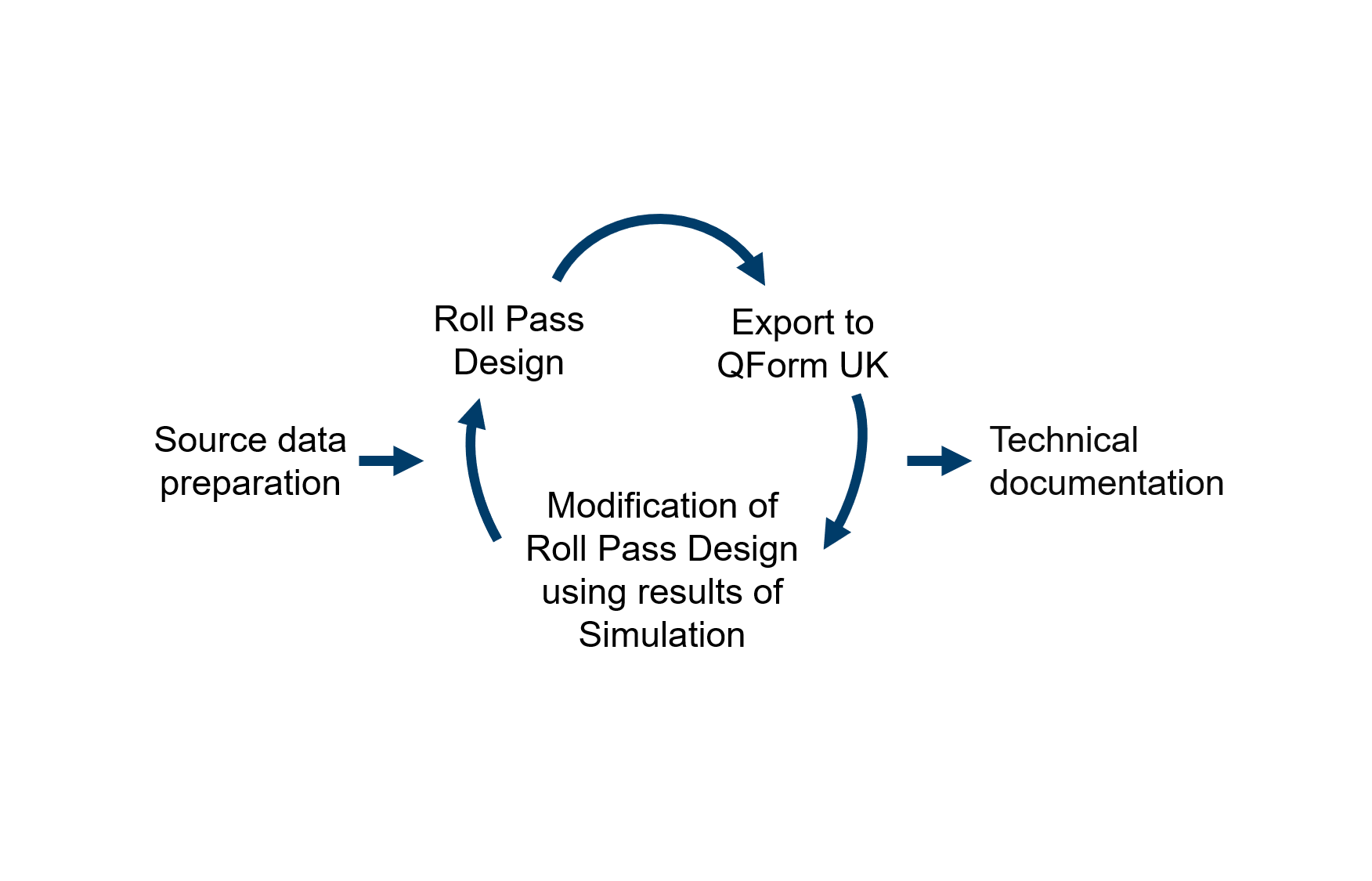

QKaliber combines calibration and simulation

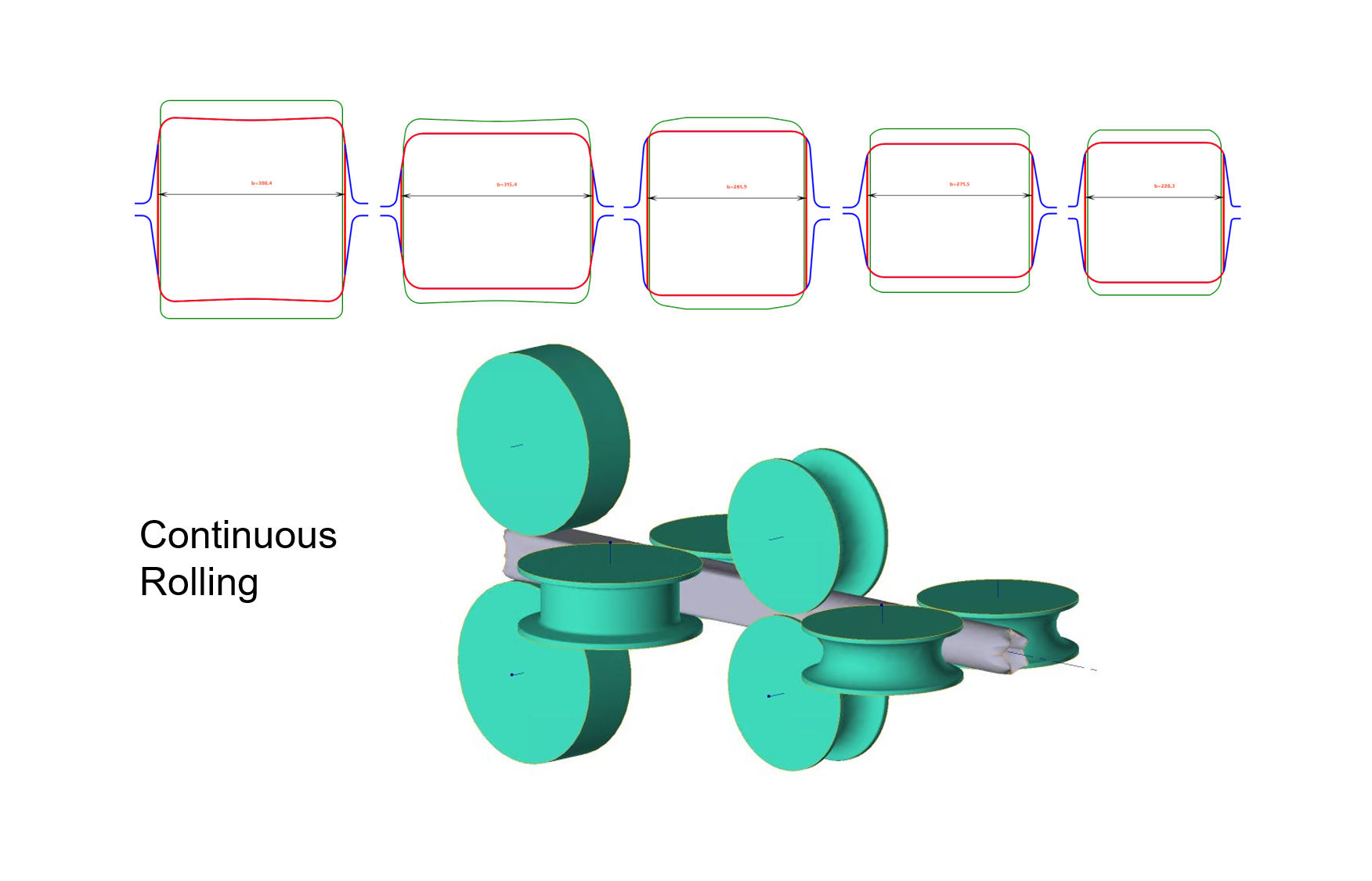

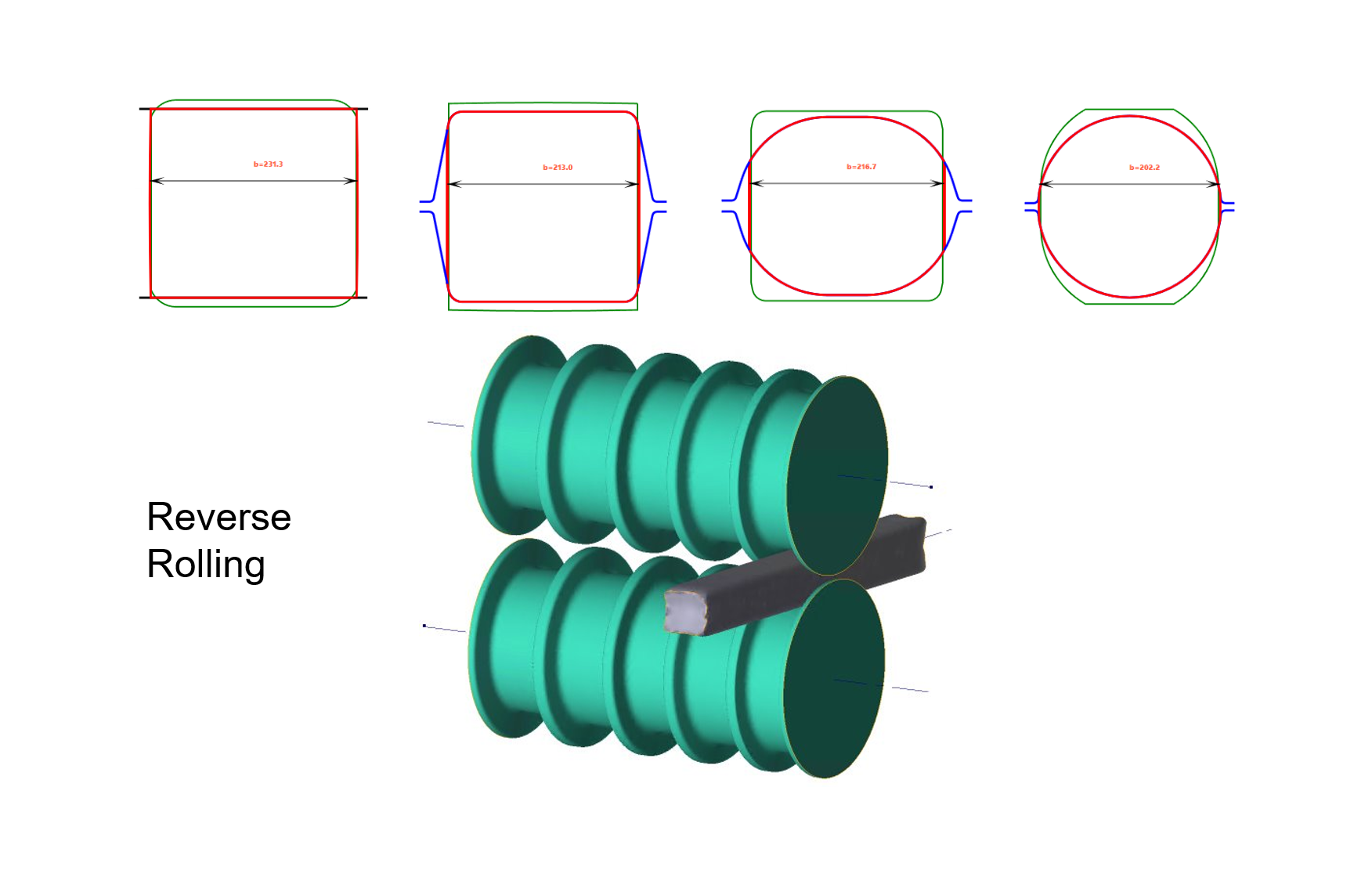

QKaliber was specifically developed for the development and optimization of rolling processes for long products and profiles. It combines calibration with simulation to offer a variety of functions, including analysis and improvement of rolling processes, simulation of forming and temperature distribution, analysis of rolling stresses and automatic generation of rolling schedules. QKaliber enables engineers to develop and implement more efficient and precise rolling technologies.

Key Features of QForm UK

QForm software products are suitable for both beginners and experts in simulation. With sufficient process knowledge, you can achieve realistic results from your first simulation. The user-friendly interface and automated algorithms regarding meshing make it easy to get started.

Economic benefits of QForm UK software products on the basis of the following features:

✔ Reduction of production lead times

✔ Elimination of process errors

✔ Improvement of product quality

✔ Reduction of material consumption

✔ Savings on test tools

✔ Shortening of development time and increased efficiency

✔ Elimination of process errors

✔ Improvement of product quality

✔ Reduction of material consumption

✔ Savings on test tools

✔ Shortening of development time and increased efficiency

Inquire for free now –

Share your requirements with us.

Share your requirements with us.

You'll receive a personalized, non-binding offer prepared by our experts.

Support & Distribution

For over a decade, GMT has been providing technical and administrative support for QForm UK and QForm UK Extrusion software products. Additionally, we offer training for QForm UK.

News

The new version QForm UK 11 has been released. For more information and the download link, please contact iris.gliewe@gmt-berlin.com or daniel.seifert@gmt-berlin.com.

Thank you to everyone who visited us at MEFORM 2024 in Freiberg/Saxony and participated in our QForm UK User Meeting in Munich! For a recap of these events, please feel free to check our News.

Thank you to everyone who visited us at MEFORM 2024 in Freiberg/Saxony and participated in our QForm UK User Meeting in Munich! For a recap of these events, please feel free to check our News.

QForm 3D Software

QForm UK allows simulation of a variety of bulk forming processes. It is supplied with extensive databases of forming materials, tool materials, lubricants and machines.

QForm UK Extrusion

QForm UK Extrusion is a special software to simulate your extrusion processes of profiles made of aluminum and other alloys. It is developed for simulation analysis of material flow during the extrusion process and for analysis of the stress-strain state of die set.

MatILDa®: Material data for FEM simulation

QForm UK also utilizes material data sets obtained from experiments stored in the MatILDa® material database. With a standard interface, material data and models can be easily integrated into the FEM software. A thorough material simulation can significantly enhance FEM results.

What is QForm UK software?

The Software QForm UK is a powerful FEM software that handles FEM simulation tasks in both 2D and 3D. Developed to enable mathematical process modeling, it finds applications in a variety of industries. QForm UK comes with standard databases for metallic materials, forming equipment, and lubricants. Additional modules allow, among other things, the import of geometries for dies and workpieces, as well as the input of 2D contours for tools and workpieces. The QForm UK FEM software package is customized according to your needs.

Where is the QForm UK FEM software used for simulation?

The FEM software QForm UK is used in a wide range of processes in cold, semi-hot and hot forming processes, particularly in the field of bulk forming. These processes include:

• cross rolling,

• longitudinal rolling,

• die forging,

• open-die forging,

• ring rolling,

• extrusion and

• electro-upsetting.

QForm UK software supports the simulation in mechanical, hydraulic and screw presses as well as forging in hammers. It's also possible to simulate longitudinal and cross rolling in individual passes or as a continuous process, whereby both flat and profiled rolls can be used. In addition, processes of extrusion can be modeled using QForm UK Extrusion.

• cross rolling,

• longitudinal rolling,

• die forging,

• open-die forging,

• ring rolling,

• extrusion and

• electro-upsetting.

QForm UK software supports the simulation in mechanical, hydraulic and screw presses as well as forging in hammers. It's also possible to simulate longitudinal and cross rolling in individual passes or as a continuous process, whereby both flat and profiled rolls can be used. In addition, processes of extrusion can be modeled using QForm UK Extrusion.

Why should I choose QForm UK for simulation?

QForm UK is globally recognized as a leading simulation program for diverse forming processes and heat treatments. It holds a prominent position in the simulation software landscape, particularly within the field of bulk forming. The crucial advantage lies in QForm UK's ability to provide realistic simulation results across a broad spectrum of industrial applications.

Save development costs with suitable simulation software

Discover the advantages of pre-simulation for your forming processes, significantly reducing development costs, tool expenses and energy costs.

Intuitive software operation even without special knowledge

QForm UK offers a user-friendly interface that allows for intuitive use of the software, even without specialized knowledge. Automated meshing algorithms make forming simulation quick and achievable without in-depth expertise. Unlike competing products, QForm UK allows for an unlimited number of elements, including nodes in the mesh or volume elements. A calculation e.g. of contact conditions can be automated in the software, but also influenced by the user.

Why GMT is your ideal partner when it comes to QForm UK

GMT has been a reliable partner for the support and sales of QForm UK for many years. Our distribution and licensing processes are handled professionally and quickly, but always individually and personally. We provide comprehensive information about licenses, costs, and QForm UK cloud licensing.

We competently assess your process in terms of its compatibility with the software

Thanks to our extensive experience and years of using QForm UK, we can competently assess whether your specific process can be optimally simulated with QForm UK. We have the expertise to assist you in independently implementing your process in QForm UK and have direct contact with the developers of QForm UK products, so that even in-depth questions can be clarified quickly.

Since 2011, we have been experts in QForm UK distribution and consulting

Since 2011, we have been the German-speaking distribution partner for QForm UK and our extensive experience is at your disposal. Our employees are familiar with various applications for 2D and 3D simulation, simulate a wide variety of processes themselves with the FEM software and write publications and conference contributions for various international magazines and events.

We are actively involved in the ongoing development of the QForm UK software

We are so familiar with QForm UK products that we actively contribute to their optimization. If any inconsistencies arise during a simulation, we report them directly to the developers so that necessary adjustments can be made.

What services does GMT offer in connection with QForm UK?

GMT offers user-oriented services and has a wide range of well-known companies among its clientele. If you're looking for a suitable FEM software for a realistic simulation of your forming process, we are here to assist you. Contact us, provide us with information about your process and we will offer an initial rough assessment of the feasibility with QForm UK. You will receive a non-binding offer.

3D simulation to represent your process

We also offer the option to accompany or carry out the initial creation of a project for the 2D or 3D simulation of your process. Benefit from our expertise in forming technology and materials and receive recommendations for your process and/or materials.

User-oriented, efficient and professional: we are here for you in the long term

At GMT, your needs are our top priority. Our goal is to ensure that you can professionally and realistically represent your processes and feel well supported by us. Even after the purchase of the product, we continue to be by your side. In addition to competent and friendly support, we offer tailor-made events for QForm UK customers. Join training sessions for the QForm UK software package or attend the user meeting, which is very much appreciated by users. Online user training is also available.