HDQT Plant: Unlocking New Property Levels through Innovative Intensive Forming

The HDQT plant redefines conventional processes by integrating an intensive forming step into a tempering facility. This groundbreaking technology opens up entirely new property levels for steels and high-strength materials.

Implementation of the Novel Forming Concept

Modern alloying and processing concepts result in high-strength steels with sophisticated property combinations. Usually, the properties of bright steel are adjusted on single-bar tempering lines by an integrated austenitizing, quench hardening and tempering process.

There have been no fundamental changes to this technical concept in the past 40 years.

There have been no fundamental changes to this technical concept in the past 40 years.

HDQT® TECHNOLOGY

HIGH DEFORMATION QUENCHING & TEMPERING

HDCR® PLANT

HIGH DEFORMATION CROSS ROLLING

HIGH DEFORMATION CROSS ROLLING

The design of the HDQT®-Technology involves integrating an intensive forming step into the layout of a conventional single-bar tempering facility. The achievable high degrees of deformation in combination with a precisely defined process temperature result in a fine microstructure with improved mechanical properties, thereby opening up advanced property levels for steels, titanium alloys, nickel-based alloys and other high-strength materials. This facility enables the implementation of various technologies that are not feasible in conventional setups. Compared to conventionally tempered material, significant increases in strength with consistent or even improved toughness properties can be achieved here.

The HDQT® plant in action: the XTP® technology

The Schmolz and Bickenbach Group has been successfully implementing this innovative forming concept as the XTP® plant since 2016. In collaboration with Steeltec, novel forming technologies are continuously implemented on this plant, achieving outstanding property classes. Explore the XTP Technology yourself.

The HDCR® plant - developed by GMT: extreme performance combined with highest precision

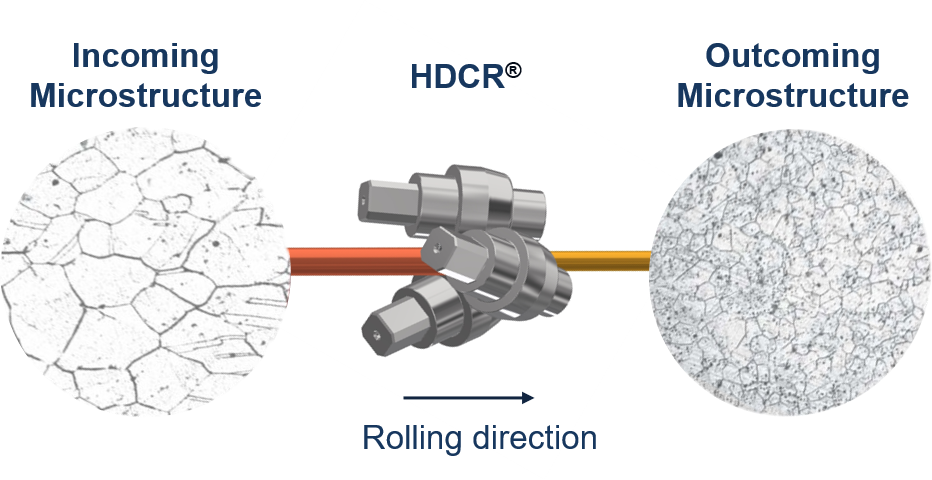

The increased requirements on products and materials raise the need for innovative plant development. With the HDCR® (High Deformation Cross Rolling) plant, the high-quality final properties and the high dimensional stability of the final part are adjusted by a repetitive incremental deformation of the initial material in a single forming step within one forming cycle. The forming process is characterized by a twisted microstructure at the case of the bar which surrounds the deformed core and leads to an increased material performance at various load conditions. Ultra-grain refining in the case region yields a graded microstructure with grain sizes in the range of one to five μm. A major advantage of the plant is the flexibility in terms of the dimensions of the rolling stock.

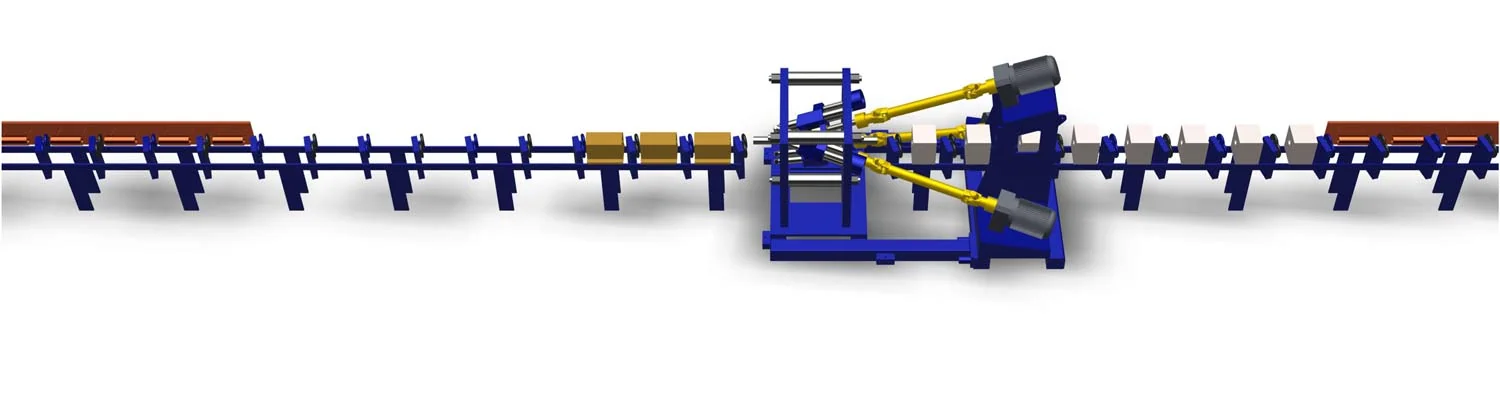

In addition, the HDQT® technology opens up optimal conditions for the development of extremely economical and flexible micro production systems. The HDCR® plant is available in different dimensions. The smallest size is designed for rolling bar in the final dimension range of 12 to 30 mm. The following stand size forms the rolled bar to a final diameter range of 18 to 40 mm with a production capacity of about two tons per hour. Larger plants up to a final diameter of up to 100 mm are also feasible when needed.

In addition, the HDQT® technology opens up optimal conditions for the development of extremely economical and flexible micro production systems. The HDCR® plant is available in different dimensions. The smallest size is designed for rolling bar in the final dimension range of 12 to 30 mm. The following stand size forms the rolled bar to a final diameter range of 18 to 40 mm with a production capacity of about two tons per hour. Larger plants up to a final diameter of up to 100 mm are also feasible when needed.

Get in touch with us.

We look forward to hearing from you