Simulation of recrystallization processes to calculate grain sizes

Growing demands for sustainability and energy efficiency require continuous material optimization. Thus, simulation is also increasingly applied in the field of forming technology and heat treatment. There is still a high potential in improving simulation results to represent forming processes realistically with the help of a sound microstructure simulation.

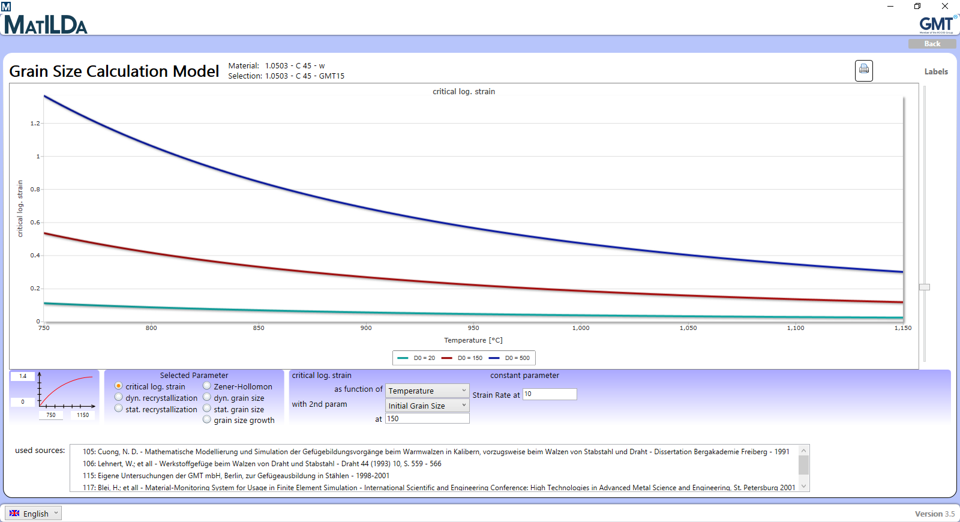

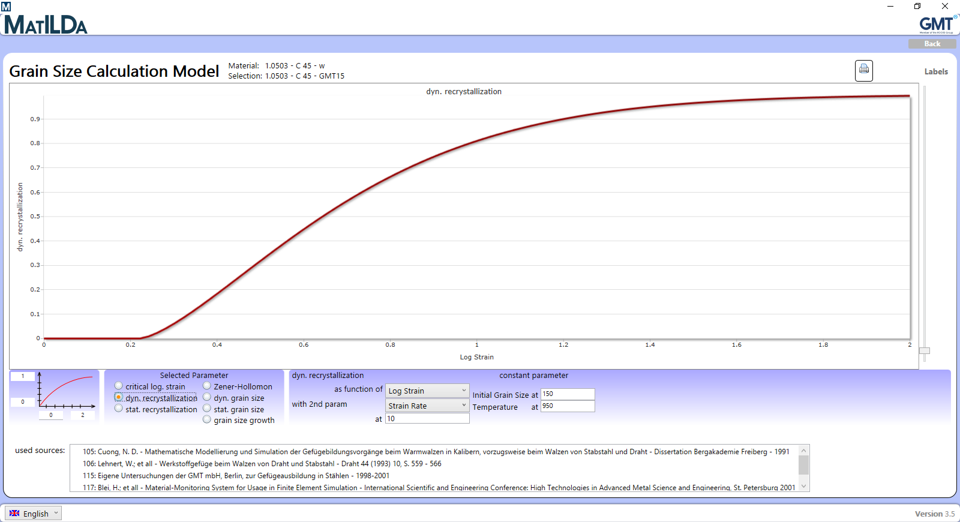

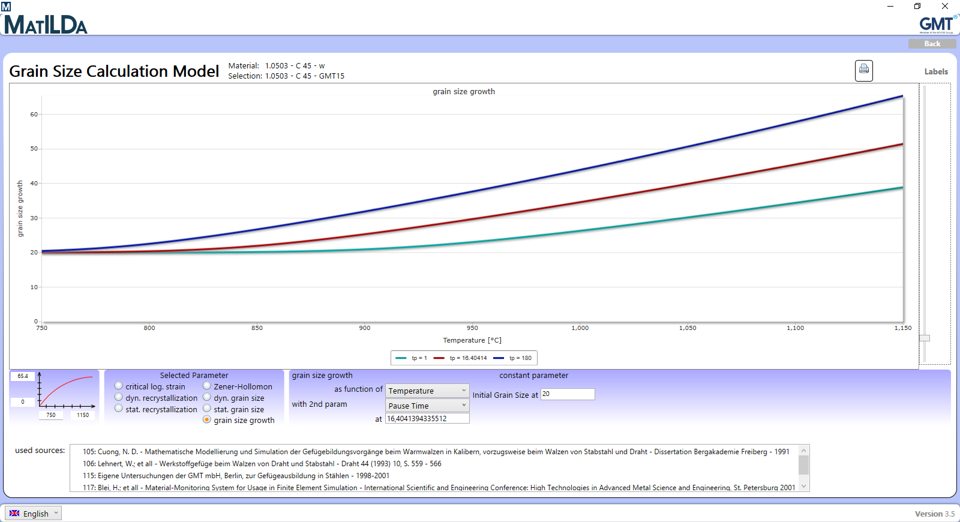

The recrystallization models in MatILDa®

The semi-empirical recrystallization model (also called grain size model or microstructure model) integrated in MatILDa® allows to calculate microstructure changes resulting from the recrystallization processes during hot forming - as well as the determination of the average grain size including hardening and softening behavior and grain growth.

During forming, metallic materials dynamically recrystallize as soon as the critical true strain for the start of dynamic recrystallization has been exceeded. The material can recrystallize statically between two forming steps, if no dynamic recrystallization took place. Thus, dynamic and static recrystallization are the most important processes involved in this kind of calculation. In this case, MatILDa® determines the associated recrystallized fractions as well as the grain sizes of the newly formed grains. The average grain size is then calculated based on the grain sizes of the recrystallized and non-recrystallized portions. Forming-induced recrystallization processes end when phase transformation starts. After completion of the recrystallization process, grain growth processes start above the recrystallization temperature (approx. 0.75 * melting temperature) of the material. The latter are also taken into account in the grain size calculation.

Validity ranges of the recrystallization models

For the recrystallisation model, it is decisive to apply the validity ranges in a simulation project. Therefore, the validity ranges are displayed in the respective model in MatILDa®. The semi-empirical approaches are based on Sellars and Whiteman.

Progress starts at micro level

The equations of the semi-empirical model can be displayed in the recrystallization model in MatILDa®. The coefficients can be adapted individually by the user. Furthermore, we are happy to support you in the acquisition and the parametrization of a new recrystallization model.

The recrystallization model is available for a wide range of steel alloys and Ni-based alloys.

The recrystallization model is available for a wide range of steel alloys and Ni-based alloys.

Please also read our publications about the recrystallization model:

Ask for more details about our recrystallization model!

✔ We have 20+ years of expertise

✔ We successfully advise and support customers from a wide range of industries

✔ Save time & costs through reliable material models for grain size calculation

✔ Your inquiry is free-of-charge & non-binding

✔ We successfully advise and support customers from a wide range of industries

✔ Save time & costs through reliable material models for grain size calculation

✔ Your inquiry is free-of-charge & non-binding

CCT database

Calculation of microstructural transformation in steels using diverse CCT diagrams, TTT diagrams or neural networks

MatILDa®

The material database for realistic material simulation